Crestone NDT

WIND TURBINE INSPECTIONS

"where integrity and quality meet"

Our non-destructive testing services provide the data you need to make meaningful decisions regarding your assets. By using the most reliable and advanced inspection technology available to us, we capable of reducing both repair costs and downtime.

our testing services

Production, inspection and testing solutions

Identifying production flaws in the early stages of the wind turbine’s life minimizes your repair costs. The benefits you will see by deploying Crestone NDT’s inspection expertise can include improvements in operational profitability and productivity.

Production

Inspection

Testing solutions

Click on graphic for magnified view.

wind turbine services

Our services within the wind turbine industry include examination of blades and components with digital eddy current and state-of-the-art automated ultrasonic scans. We are always on the lookout for the most advanced inspection technologies and delivery systems (i.e. robotics and UAVs) but the most common testing methods used include:

- Ultrasound (UT)

- Magnetic particle (MT)

- Liquid penetrant (LT)

- Remote controlled visual testing (VT)

- Phased Array ultrasound (PAUT)

- Eddy Current (ET)

- Borescope

We are able to perform ultrasonic weld inspections on wind turbine towers and foundations with 100% documentation of all tests performed.

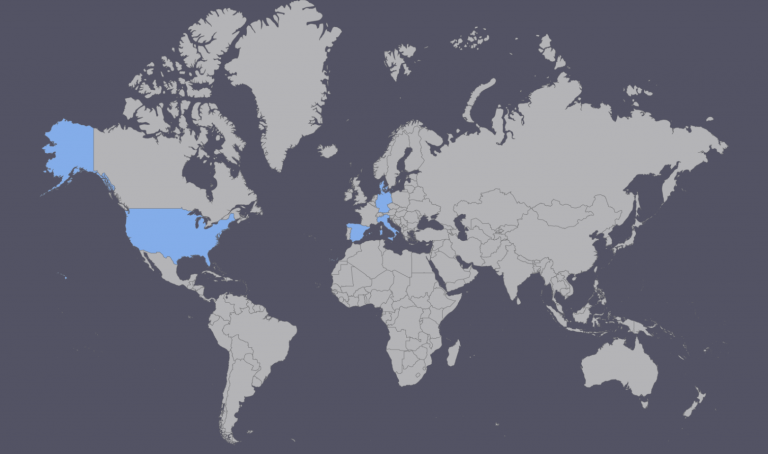

world wide

Regions Served

regions served

We can deploy both domestically (USA) and internationally while meeting the inspection requirements/procedures for wind turbines manufactured in these different European Countries (Germany, Italy, Spain and Holland).

We are also capable of deploying both to onshore and offshore wind turbine locations.

reporting commitment

We commit to prepare a timely report that accurately reflects the inspection findings. Our report will also include clearly labeled repair recommendations.