NDT Services

Unique and Effective Solutions

click on a heading below to expand each technique

Examples:

- Non-confined Space (out-of-service) Tankfloor Robotic Inspection Solution

- In-Service Tankfloor (through Sludge) and Critical Zone Robotic Design

- Permanently Installed UT/Shearwave/Phased Array Probe Installation/Monitoring

- Drone Delivered UT B-Scan Robot

- Custom Robotic Development for Visual/ACFM/Eddy Current of Welds on Separator Screw

- DRONE INSPECTION

- AEROPACE INSPECTIONS

- ULTRASONIC FLAW DETECTION

- ADVANCED ULTRASONIC B-SCAN

- AUT CORROSION MAPPING

- SLOFEC

- API 653 STORAGE TANK INSPECTION

- FLOOR SCANNING (Both MFL and SLOFEC)

- VACUMM BOX TESTING

- SETTLEMENT SURVEY

- ADVANCED ULTRASONIC B-SCAN

- VESSEL (API 510) INSPECTIONS

- DRONE INSPECTIONS

- SLOFEC PIPE SCANNER (Both External and Internal Robotics)

- AUT CORROSION MAPPING

- API 570

- RADIOGRAPHY TESTING (RT)

- PENATRANT TESTING (PT)

- MAGNETIC PARTICLE TESTING (MT)

- ULTRASONIC TESTING (UT)

- VISUAL TESTING (VT)

- POSITIVE MATERIAL IDENTIFICATION (PMI)

- BRINELL HARDNESS TESTING (BHT)

- ACCURATELY QUANTIFY VOLUME OF SLUDGE IN FLOATING ROOF CRUDE OIL STORAGE TANKS

- USES PATENTED SONAR TECHNOLOGY TO SCAN SLUDGE ON BOTTOM OF TANKFLOOR

- OBTAIN QUANTITATIVE VOLUMETRIC DATA OF THE SLUDGE

- ATEX CERTIFIED INTRINSICALLY SAFE

Inspection Services

Featured Services

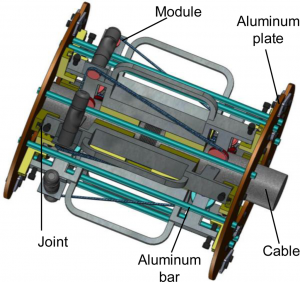

Internal (SLOFEC) Pipe Inspection

Custom Robotic and Technology Solutions

- Try using or modifying off-the-shelf solutions to save our clients' money.

- Respond with quick turnaround designs and inspection solutions.

- Work with the Best-in-Field NDT and Robotic Professionals to fill in knowledge and capability gaps.

API 653 Tank Inspection

- General Tank Information: Review tank description information.

- Tank Bottom, Tank Shell, and Tank Roof Inspections: API 653 allows different types of inspection to examine the aboveground tank components.

- Bottom, Shell and Roof: The structure of the tank is inspected to API 653 standards.

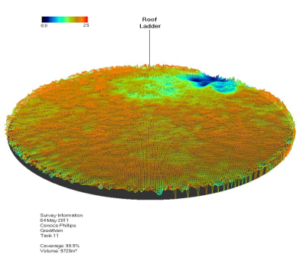

- Settlement Evaluations: Examine whether the tank is tilting or settling in the ground improperly.

NORM and TENORM Services

With over 60 years of combined NORM experience, we train our clients' team members to confidently (and safely) manage and handle the NORM and TENORM that is far more prevalent than most Operators realize.

Radiography Inspection

Our customers will often request specialty services that we or others are unable to perform. Once we know of these needs, we do our best to find the solution. Whether it has already been developed or if we develop it ourselves, we find unique and effective solutions.

Only a select few companies in the world offer both conventional and advanced inspection techniques.

Crestone NDT IS ONE OF THEM.

slide the button below to read more on these techniques

SLOFEC

MFL

what is slofec?

The SLOFEC (Saturated Low Frequency Eddy Current) inspection system is based on the eddy current principle with superimposed DC field magnetization.

With this system objects with up to 25 mm wall thickness and coating up to 10 mm are testable, depending on the scanner type.

The task of the inspection system is to detect defects in tank floors, walls and roofs as well as in pipe walls. Due to the phase spread between subsurface (outside), surface (inside) and other indications the SLOFEC™ Operator is able to distinguish them from each other. Objects with non-conductive and non-magnetic coating, like rubber or paint, are also testable. A special coupling medium is not necessary.

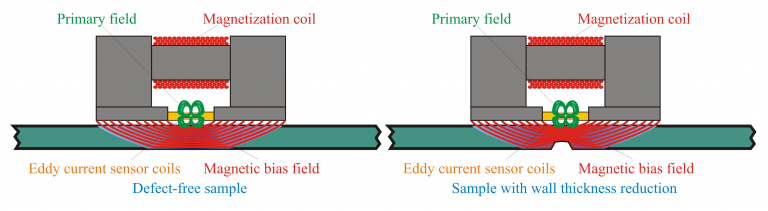

The figure schematically shows the working principle of the SLOFEC® technique. A magnetic yoke containing a permanent or electro-magnet is used to generate a strong magnetic field in the material to be tested. The magnetic DC field has an effect to the material properties of the test sample.

Between the poles of the yoke an eddy current sensor array is located. These sensors also generate a small alternating magnetic field in the material under test, super-imposed to the magnetic bias field of the yoke. The eddy current field is sensitive to changes of the material properties of the test sample. In a defect-free sample the magnetic bias field and therefore the material properties do not change. As a result the eddy current signal is unchanged.

A reduction of the wall thickness, e.g. by a corrosion pit will result in a concentration of the magnetic fields in the remaining wall and resulting in an increased magnetic field strength above and around the defect. This results in a Change of the material properties at this location. This local change of the material properties will be detected by the eddy current sensor.

The eddy current signal amplitude of the defect indication is a measure for the volume of metal loss.

what is mfl?

Magnetic Flux Leakage (MFL) inspection is a method of NDT used to detect and assess corrosion, pitting and wall loss in lined and unlined metallic storage tanks and pipelines.

Magnetic flux is the product of the average magnetic field times the perpendicular area that it penetrates. It is a quantity of convenience in the statement of Faraday’s Law and in the discussion of objects like transformers and solenoids.

In tank floor inspection, the floor of the tank is swept with the MFL tool. The area is flooded with magnetic flux and rare earth magnets are used to temporarily magnetize the steel while the magnetic field changes are recorded and analyzed. If the magnetic field is uniform, there are no flaws in the tank floor. If the magnetic field is distorted, internal or external flaws are present, such as pitting or corrosion and this distortion or “leakage” can be measured by the sensors.

Technicians proceed to mark areas that need to be verified by visual and ultrasonic inspections. The results obtained from the MFL inspection can be reported and used to establish an existing baseline for the equipment or to determine remaining wall and fit-for-service corrosion calculations in accordance with API, EEMUA and other applicable standards.